Kugadzirwa kwepurasitiki chikamu chakakosha chakakosha munharaunda yemazuva ano nekuti inopa zvigadzirwa zvakasiyana-siyana zvinoshandiswa muhupenyu hwezuva nezuva. Plastiki inoshandiswa kugadzira zvinhu zvakaita sekurongedza, magaba, midziyo yekurapa, matoyi, uye zvemagetsi. Inoshandiswawo mukuvaka, maindasitiri emotokari, uye endege. Plastiki yakareruka, inogara kwenguva refu, uye inodhura zvishoma, zvichiita kuti ive chinhu chakanakira mashandisirwo mazhinji. Pamusoro pezvo, mamwe mapurasitiki anogona kudzokororwa, zvichiita kuti ive sarudzo isingakuvadzi nharaunda.

Kune vagadziri vepurasitiki, vanowanzo zvipira kugadzirisa mashandiro epurasitiki zvakanaka uye kuti vangawana sei kupedzisa kwakanaka pamusoro pezvikamu zvepurasitiki. Nekuti zvinogona kubatsira kuderedza mari yekugadzira, kuvandudza mhando yechigadzirwa, uye kuwedzera hupenyu hwezvikamu. Pamusoro pezvo, kupedzisa kwakanaka pamusoro kunogona kubatsira kuderedza kukweshana nekupfeka, izvo zvinogona kubatsira kuvandudza mashandiro ezvikamu. Pakupedzisira, kupedzisa kwakanaka pamusoro kunogonawo kubatsira kuvandudza runako rwezvikamu, zvichiita kuti zvinyanye kukwezva vatengi.

Nzira yekuvandudza kushanda zvakanaka kwekugadzirwa kwepurasitiki uye kunaka kwenzvimbo?

Kazhinji, kune nzira dzakawanda dzekuvandudza kugadzirwa kwepurasitiki uye kunaka kwayo pamusoro. Izvi zvinosanganisira: kushandisa PE, PP, PVC, PBT, PET, ABS, PC, nezvimwe zvinhu zve thermoplastic, kugadzirisa maitiro ekuumba majekiseni, kushandisa nzira dziri nani dzekutonhodza, uye kushandisa nzira dzekugadzirisa mushure mekugadzira dzakadai sekupukuta nekuputira. Pamusoro pezvo, kushandisa zvimwe zvinhu zvakaita sekuwedzera kwekugadzirisa, mafuta ekuzora, uye zvinoburitsa zvinogona kubatsira kuvandudza hunhu hwekugadzirisa, kubereka, uye kupenya kwenzvimbo dzepurasitiki.

Silicone ndeimwe yemidziyo yepurasitiki inonyanya kufarirwa inoshandiswa kuvandudza mashandiro ekugadzirisa uku ichigadzirisa hunhu hwepamusoro, sekuvandudza nzvimbo yakatsetseka, kuderedza coefficient yekukweshana, kuramba kukweshana, kuramba kukweshana, uye kunyorova kwemapolymers. Iyo midziyo yakashandiswa mumhando dzemvura, pellet, uye upfu, zvichienderana nezvinodiwa nepurasitiki.

Pamusoro pezvo, zvakaratidzwa kuti vagadziri vemhando dzese dzethermoplastics nemapurasitiki einjiniya vanoedza kuvandudza mwero wekubuda kwechinhu, kuwana kuzadza kwechinhu nguva dzose, kuburitsa chinhu, kunaka kwepamusoro, kuderedza kushandiswa kwesimba, uye kubatsira kuderedza mitengo yesimba, zvese izvi pasina kugadzirisa michina yemazuva ano yekugadzirisa. Vanogona kubatsirwa nezvinowedzera zvesilicone, uye kubatsira kuedza kwavo kugadzira zvinhu kuti zvive nehupfumi hwakatenderera.

Chengdu Silike Technology Co., Ltd inyanzvi yekugadzira silicone mumunda wekushandisa rabha nepurasitiki muChina, yakatungamira mukutsvaga SILICONE nePLASTIC (misanganiswa miviri yakafanana yekudyidzana kwakasiyana), ichitarisa paR&D yezvinowedzera zvesilicone kwemakore anopfuura makumi maviri. uye yakagadzira zvigadzirwa zvakasiyana zvesilicone.silicone masterbatch, upfu hwesilicone, masterbatch inodzivirira kukwenya, amasterbatch yekudzivirira abrasion, mafuta eWPC,super slip masterbatch, Silimer silicone wax, masterbatch inodzivirira kurira,silicone murazvo unodzora moto synergist, PPA, silicone molding,chingamu chesilicone,zvimwe zvinhu zvakagadzirwa nesilicone,Si-TPVuye zvimwe…

Izvi zvinowedzerwa zvesilicone zvinobatsira kuvandudza hunhu hwekugadzirisa zvinhu zvepurasitiki uye kunaka kwepamusoro pezvikamu zvakapedzwa zvemukati memotokari, tambo nemidziyo yemagetsi, mapaipi epurasitiki, shangu, firimu, machira, midziyo yemagetsi yemumba, mapuranga epurasitiki, zvikamu zvemagetsi, nezvimwe zvinhu zvemagetsi.

Zvishandiso zveSilike's silicone zvinopa Nzira dzekuvandudza kugadzirwa kwepurasitiki uye kunaka kwenzvimbo, izvo zvinopa Kupedzisa Kwakanaka paZvikamu zvePurasitiki. Chigadzirwa cheSILIKE's silicone chinoshandiswa zvakanyanya mukugadzira majekiseni, kugadzira ma extrusion, uye kugadzira ma blow molding.

Uyezve, kuwana silicone yakakodzera application yako hakungogumiri paSILIKE's product portfolio. Chikwata chedu chehunyanzvi chichashanda pamwe chete newe kugadzirisa magadzirirwo echigadzirwa chiripo kana kugadzira chitsva kuti chienderane nezvinodiwa zvako chaizvo. Chinhu chikuru ndechekuti tinogona zvakare kugadzirisa chigadzirwa chitsva zvichienderana nezvinodiwa nevatengi, resin inoenderana, uye molecular-weight silicone content zvinoenderana, nekuda kwetekinoroji yedu huru iri iyo inodzora chimiro chePDMS…

Chii chinonzi silicone?

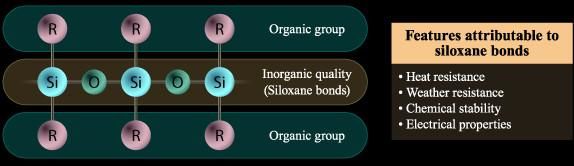

Silicone chinhu chisina kugadzirwa, Chimiro chikuru chesilicon chinoumbwa nepolyorganosiloxanes, uko maatomu esilicon anobatanidzwa neokisijeni kuti agadzire chisungo che "siloxane". Ma valence asara esilicon ane chekuita nemapoka eorganic, kunyanya mapoka emethyl (CH3): Phenyl, vinyl, kana hydrogen.

Si-O bond ine hunhu hwesimba guru remapfupa, uye hunhu hwakasimba hwemakemikari uye pfupa reSi-CH3 rinotenderera pfupa reSi-O zvakasununguka, saka kazhinji silicone ine hunhu hwakanaka hwekudzivirira kupisa, hunhu hwakaderera uye hwepamusoro-soro, hunhu hwakasimba hwemakemikari, kusagadzikana kwakanaka kwemuviri, uye simba shoma repamusoro. Izvi zvinoita kuti zvishandiswe zvakanyanya mukugadzirisa mapurasitiki uye mhando yepamusoro yezvinhu zvakapedzwa zvemukati memotokari, tambo newaya, mapaipi ekutaurirana, shangu, firimu, kuputira, machira, midziyo yemagetsi, kugadzira mapepa, kupenda, kupa rubatsiro rwemunhu, uye mamwe maindasitiri. Inoremekedzwa se "industrial monosodium glutamate".

Nguva yekutumira: Chivabvu-11-2023