Polycarbonate (PC) ndeimwe yezvigadzirwa zve thermoplastics zvinoshandiswa zvakanyanya mumalenzi emotokari, zvigadzirwa zvemagetsi, maziso, uye zvishandiso zvekudzivirira. Simba rayo guru, kujeka kwayo, uye kugadzikana kwayo muzvikamu zvinoita kuti ive yakakodzera kushandiswa kwakasimba. Zvisinei, dambudziko rinozivikanwa rePC nderekuti haina kusimba pamusoro, izvo zvinoita kuti isakwenyeke uye isapfekwe zvakanaka—kunyanya kana ichibatwa kakawanda kana kuti ichikwesha.

Saka, vagadziri vanogona sei kuwedzera kugara kwenguva refu kwePC vasingakanganisi kujeka kwayo kana hunhu hwayo hwemakanika? Ngationgororei mhinduro dzakasiyana-siyana dzinoshanda uye matekiniki akasimbiswa neindasitiri kuti tikunde matambudziko aya.

Mhinduro: Sanganisa zvinhu zvinovandudza mashandiro ekugadzirisa uye kugadzirisa zvivakwa zvepamusoro nehunyanzvi hwekudzivirira hwepamusoro.

1. Zvinowedzerwa neSilicone: Kunyorovesa kwemukati

Kuisa zvimwe zvinowedzerwa zvesilicone zvine simba guru, zvakaita sepolydimethylsiloxane (PDMS) kana siloxane-based masterbatches zvakaita seDow MB50-001, Wacker GENIOPLAST, uye SILIKE Silicone Masterbatch LYSI-413, mu polycarbonate (PC) formulations kunogona kuwedzera kushanda kwechinhu chacho zvakanyanya. Nekushandisa izvi zvinowedzerwa padanho re 1-3%, unogona kuderedza coefficient of friction zvinobudirira, izvo zvinovandudza resistance scratch uye sustainability.

Mabhenefiti Akakosha: Izvi zvinowedzerwa zvesilicone, sezvinhu zvinogadzirisa PC uye zvinogadzirisa, hazvingochengetedze kujeka kwePC chete asiwo zvinosimudzira kunyorova kwepamusoro. Izvi zvinoderedza kukuvara kwepamusoro panguva yekubata abrasive, zvichizopedzisira zvaita kuti chigadzirwa chigare kwenguva refu.

Zano Rinoshanda: Kuti uve nechokwadi chekuti zvinhu zvinoshanda zvakanaka, zvakakosha kuti zvinhu zvipararire zvakanaka kuburikidza nekubvisa zvinhu zvine screw mbiri, izvo zvinobatsira kudzivirira kupatsanurwa kwezvikamu uye kuwedzera mabhenefiti ezvinowedzera.

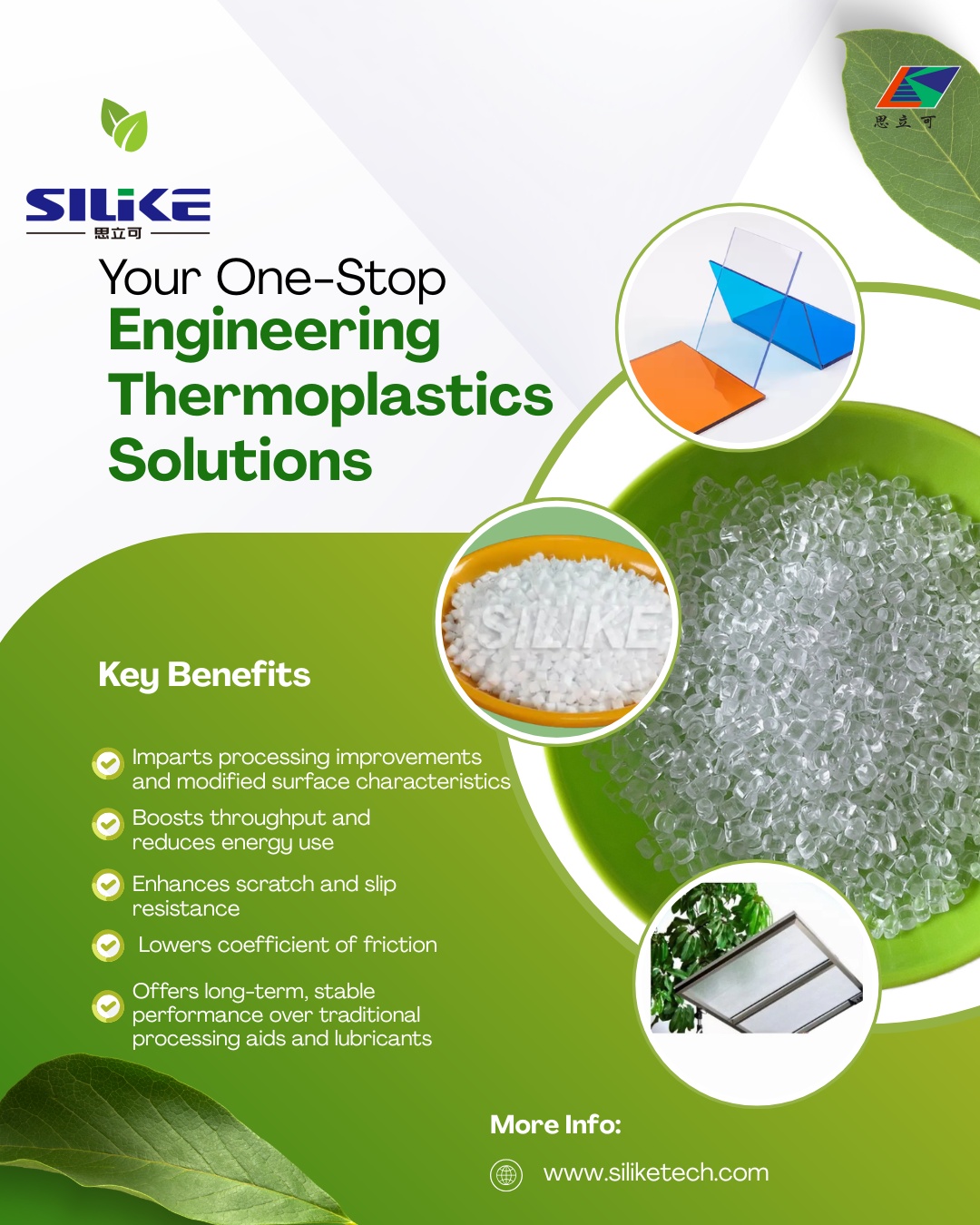

Chengdu SILIKE Technology Co., Ltd ikambani inotungamira mukutengesa zvinhu zveChina.zvishongedzo zvesilicone zvepurasitiki dzakagadziriswaKambani iyi inopa mhinduro itsva dzakagadzirirwa kusimudzira mashandiro uye mashandiro emhando dzakasiyana dzepurasitiki. Chimwe chezvinhu zvavo zvinoshamisa iSILIKE Silicone Masterbatch LYSI-413,mushonga unoshanda zvikuru une 25% ultra-high molecular weight siloxane polymer yakapararira mu polycarbonate (PC). Uyu mushonga unobva kusilicone unoshanda zvakanyanya kune ma resin anoenderana nePC. Unovandudza hunhu hwekugadzirisa uye kunaka kwenzvimbo nekuwedzera kuyerera kwe resin, zvichiita kuti ikwanise kuzadza nekusunungura mold, kuderedza extruder torque, kuderedza coefficient of friction, uye kupa simba rekudzivirira mar ne abrasion. Pamusoro pezvo, iyi siloxane-based masterbatch inoshanda semushonga unodzivirira kukwenya, zvichiita kuti ive mhinduro yakanaka yekuwedzera kukwenya kwezvigadzirwa zvePC uye pakupedzisira inovandudza mashandiro azvo ese uye kugara kwenguva refu.

2. Mapepa Akaoma Anorapika NeUV Achishandisa Nanotechnology

Isa machira akaomarara emhando yepamusoro akavakirwa pa siloxane kana kuti akasanganiswa ne organic-inorganic (semuenzaniso, Momentive SilFORT AS4700 kana PPG's DuraShield). Machira aya anowedzera kuomarara kwepenzura kusvika pa7H-9H, zvichiwedzera zvakanyanya kuramba kukwenya.

Isa machira anorapika neUV ane nanoparticles (semuenzaniso, silica kana zirconia) kuti uwedzere kuramba kukwesha.

Kubatsira: Inopa chidziviriro kubva pakukwenya, makemikari, uye kuora kweUV, yakakodzera kushandiswa kwemaziso nemotokari.

Kushandisa: Shandisa dip-coating, spray-coating, kana flow-coating kuti ukobvu hwakaenzana (5-10 µm).

3. Kusimbiswa kweNanocomposite

Wedzerai nanofillers dzakadai se nanosilica, alumina, kana graphene oxide (0.5-2% nehuremu) kuPC matrix. Izvi zvinowedzera kuomarara kwenzvimbo uye zvinovandudza kuramba kupfeka pasina kukanganisa kujeka zvakanyanya kana saizi ye particle iri pasi pe40 nm.

Muenzaniso: Zvidzidzo zvinoratidza kuti 1% nanosilica muPC inogona kuwedzera kuramba kweTaber abrasion ne20-30%.

Zano: Shandisa zvinhu zvinobatanidza zvinhu (semuenzaniso, zvinhu zvinobatanidza silane) kuti uve nechokwadi chekuti zvinhu zvinopararira zvakaenzana uye kudzivirira kuungana kwechinhu.

4. Misanganiswa yePC yekushanda zvakanaka

Sanganisa PC nePMMA (10-20%) kuti uwedzere kuomarara kwepazasi kana nePBT kuti iwedzere kusimba uye kusakara. Izvi zvinosanganisa kusimba kwekukwenya nePC.

Muenzaniso: Musanganiswa wePC/PMMA ne15% PMMA unogona kuwedzera kuomarara kwenzvimbo uku uchichengetedza kujeka kwemashandisirwo ekuratidzira.

Chenjero: Gadzirisa huwandu hwemusanganiswa kuti usakanganisa kugadzikana kwekupisa kwePC kana kusimba kwayo.

5. Matekiniki Epamusoro Ekugadzirisa Pamusoro

Kurapa Plasma: Isa plasma-enhanced chemical vapor deposition (PECVD) kuti uise machira matete, akaomarara akadai sesilicon oxynitride (SiOxNy) pamusoro pePC. Izvi zvinovandudza kuramba kukwenya uye hunhu hwekukwenya.

Kugadzira Magadzirirwo eLaser: Gadzira magadzirirwo madiki kana madiki pamusoro pePC kuti uderedze nzvimbo yekubata uye kuparadzanisa mavanga, zvichivandudza kugara kwenguva refu kwerunako.

Kubatsira: Kugadzira machira kunogona kuderedza kukwenya kunoonekwa ne40% muzvishandiso zvinobata ganda zvakanyanya.

6. Musanganiswa wekuwedzera wekubatana

Sanganisa zvinhu zvinowedzerwa zvesilicone nezvimwe zvinhu zvinoshanda zvakaita sePTFE (polytetrafluoroethylene) micropowders (0.5-1%) kuti zvive nemhedzisiro inoshanda. PTFE inowedzera kunyorova, ukuwo silicone ichivandudza kuramba kupfeka.

Muenzaniso: Musanganiswa we 2% silicone masterbatch ne 0.5% PTFE unogona kuderedza kupera simba ne 25% mukushandiswa kwe sliding.

7. Mamiriro Ekugadzirisa Akagadziriswa:

Shandisa musanganiswa wepamusoro-soro kuti uparadzire zvinowedzerwa uye zvinozadza zvakaenzana. Chengetedza tembiricha yekugadzira PC (260-310°C) kudzivirira kuora.

Shandisa nzira dzekugadzira nemazvo (semuenzaniso, kugadzira majekiseni uchishandisa maforoma akakwenenzverwa) kuderedza zvikanganiso zvepadenga zvinogona kukonzera kukwenya.

Zvikamu zvakaumbwa zvine anneal pa 120-130°C kuderedza kushushikana kwemukati, zvichivandudza mashandiro ekupfeka kwenguva refu.

Kutarisa Zvinhu Zvitsva: Kuzviporesa uye Kupfeka DLC Zviri Kukura

Matekinoroji ari kusimukira akadai semachira ekuzviporesa (akavakirwa pa polyurethane kana siloxane chemistry) uye machira akafanana nedhaimani (DLC) anopa mhinduro dzinoshanda mune ramangwana dzemapurogiramu emakombiyuta anogara kwenguva refu uye anobata-bata zvakanyanya. Kunyange zvazvo zvichiri zvisingadhuri pazvigadzirwa zvakawanda, matekinoroji aya anoratidza tarisiro muzvigadzirwa zvemagetsi zvemhando yepamusoro, mota, uye zvemuchadenga.

Nzira Inokurudzirwa Yekushanda Zvakanaka MuThermoplastics Yeinjiniya

Kune vagadziri vari kutsvaga mhinduro inoshanda uye inokwanisika yekuvandudza kugara kwenguva refu kwePC, tinokurudzira:

1)2% UHMW Silicone chinowedzera pakunyorovesa kwemukati

2) Kuputira UV kwakavakirwa paSiloxane + 1% Nano Silica yekuoma kwenzvimbo

3) Micro-Texturing kuburikidza neLaser Molding kuviga mavanga

Maitiro aya ane mativi matatu anopa chiyero chekushandisa mari zvakanaka, kuenderana kwekugadzirisa, uye mashandiro, zvichiita kuti ive yakakodzera zvigadzirwa zvinopfekwa zuva nezuva uye zvinoda runako runogara kwenguva refu.

Zvakaratidzwa neIndasitiri

Sekureva kwemushumo wegore ra2024 weMarketsandMarkets, musika wepasi rose wezvokuputira zvakasimba unotarisirwa kudarika mabhiriyoni emadhora $1.3 panosvika gore ra2027, zvichikonzerwa nekukura kwekudiwa kwepurasitiki inodzivirira kukwenya muzviratidziro zvemotokari, nharembozha, uye malenzi emaziso. Maformula ezvinhu uye macompound anobatanidza zvinowedzera zvinoshanda uye nano-fillers akagadzirira kutungamira chizvarwa chinotevera chezvigadzirwa zvePC zvakasimba.

Wakagadzirira kuwedzera mapurasitiki ako einjiniya akadai sePC nekudzivirira kukwenya uye kupera zviri nani?

Ongorora SILIKEchinowedzera chepurasitikimhinduro dzinovandudza mashandiro ekugadzirisa uye hunhu hwepamusoro kuti zvigutse zvaunoda kuti ugare kwenguva refu.

For further information, please visit our website at www.siliketech.com, or contact us at Tel: +86-28-83625089 or via email at amy.wang@silike.cn. we provide mhinduro dzinoshanda dzekugadzirisa mapurasitiki.

Nguva yekutumira: Chikunguru-02-2025