Polyamide resin, yakapfupikiswa sePA, inozivikanwa senylon. Iyuniti huru inodzokororwa ine maamide groups mupolymer yezwi rekuti general term. Mapurasitiki mashanu einjiniya ari mukugadzirwa kukuru, marudzi mazhinji, marudzi anoshandiswa zvakanyanya, uye mamwe mapolymer blends uye alloys, nezvimwewo, anosangana nezvinodiwa zvakasiyana, zvinoshandiswa zvakanyanya sechinzvimbo chesimbi, huni, nezvimwe zvinhu zvechinyakare.

PA6 chinhu chenaironi, chine simba remuchina rakakwira asi rakaderera pane PA66; simba rekudhonza, kuomarara pamusoro, uye kuomarara kwakakwira kupfuura mamwe mapurasitiki enaironi, uye kuramba simba uye kuchinjika kupfuura PA66.

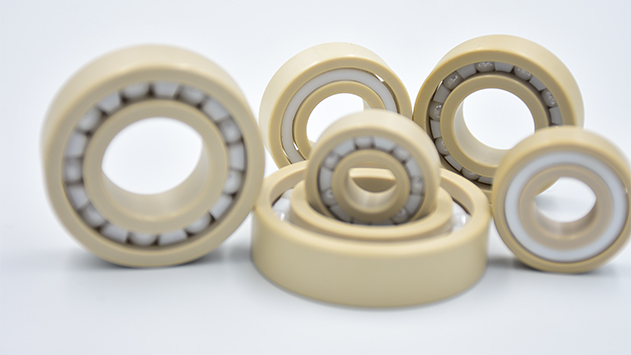

Kugadzirwa kwepurasitiki yePA6 nylon inoshandiswa zvakanyanya mukugadzira mabheringi, magiya akatenderera, makamera, magiya ebevel, maroller akasiyana-siyana, mapulley, mapombi ekufambisa, mafeni, magiya ehonye, mapropeller, masikuruu, nzungu, magasket, zvisimbiso zvine simba guru, magasket anodzivirira mafuta, midziyo inodzivirira mafuta, mahosi, mahosi, jira rekuisa tambo, uye zvinhu zvinodiwa zvezuva nezuva nefirimu rekurongedza nezvimwewo.

PA6 inowanzoshandiswa mukuumba majekiseni, kuumba ma extrusion, nedzimwe nzira dzekugadzirisa. Munguva yekugadzirisa, PA6 inogona kunge iine mamwe matambudziko akajairika, anosanganisira:

Kuyerera kusina kunaka kwekunyunguduka: PA6 ine kunyunguduka kwakanyanya, izvo zvinokonzeresa kuyerera kusina kunaka kwekunyunguduka uye zvinokanganisa kunaka kwekuumbwa kwechigadzirwa. Kunyunguduka kwekunyunguduka kunogona kuvandudzwa nekugadzirisa tembiricha yekugadzirisa uye kuwedzera kumanikidzwa kwejekiseni.

Kudzikira kukuru: PA6 ichave nekudzikira kukuru panguva yekutonhodza, izvo zvinozotungamira nyore nyore kukura kwechigadzirwa chisina kugadzikana kana kushanduka. Kudzikira kunogona kuderedzwa nekugadzira chimiro chechiumbwa zvine musoro uye kudzora kumhanya kwekutonhodza.

Mabhurumu uye maburi: Mukuumbwa kwejekiseni, PA6 inogona kuburitsa mabubbles uye porosity nekuda kwegasi retsvina kana kuyerera kusina kunaka kwekunyunguduka, zvichikanganisa kunaka kwepamusoro pechigadzirwa. Kugadzirwa kwemabubbles uye porosity kunogona kuderedzwa nekugadzirisa chimiro chemold uye kuwedzera tembiricha yekunyunguduka.

Kudzivirira kusakara pamusoro: PA6 inowanzoitika pakukwenya panguva yekuumbwa kwejekiseni kana kubudiswa, izvo zvinokanganisa kunaka kwechigadzirwa uye nokudaro zvinoderedza hupenyu hwebasa rechigadzirwa. Mukugadzirisa mapellets ePA6 kunogona kuwedzera huwandu hwakakodzera hwesilicone masterbatch, kuburikidza nekushandurwa kwezvinhu zvePA6, kuvandudza mashandiro ekugadzirisa zvidimbu zvePA6, kudzivirira mhando yezvigadzirwa zvinokanganiswa.

Kudzivirira kusakara pamusoro peSILIKE Silicone Masterbatch——Kubatsira kusimudzira indasitiri yepurasitiki yeinjiniya

SILIKE Silicone Masterbatch LYSI-407imhando yepelletized ine 30% ultra-high molecular weight siloxane polymer yakapararira muPolyamide-6 (PA6). Inoshandiswa zvakanyanya sechinhu chinobatsira pakugadzirisa ma resin anoenderana nePA6 kuti ivandudze hunhu hwekugadzirisa uye kunaka kwenzvimbo, zvakaita sekugona kuri nani kuyerera kwe resin, kuzadza & kusunungura mold, torque shoma ye extruder, low coefficient of friction, uye greater mar and abrasion resistance.

Ndezvipi zvakanakira kuwedzera huwandu hwakakodzera hweSILIKESilicone Masterbatch LYSI-407mukuita kwegranulation?

(1) Kuvandudza hunhu hwekugadzirisa zvinhu zvinosanganisira kugona kuyerera zvakanaka, kuderedza madonhwe emvura anobuda, torque shoma yekubudisa zvinhu, kuzadza nekusunungura zviri nani molding filling & release.

(2) Kuvandudza kunaka kwenzvimbo yakaita sekutsvedza kwenzvimbo uye kudzikisa Coefficient yekukweshana.

(3) Kudzivirira kukuru kwekukwenya nekukwenya

(4) Kuburitswa kwemagetsi nekukurumidza, kuderedza mwero wekukanganisa kwechigadzirwa.

(5) Wedzera kugadzikana kana tichienzanisa nezvinhu zvekushandisa pakugadzira kana mafuta ekushandisa

Ndezvipi zvinhu zvinoshandiswa pakushandisaSILIKE Silicone Masterbatch LYSI-407?

(1) PA6, PA66 makemikari

(2) Makemikoro ePA egirazi fiber

(3) Mapurasitiki einjiniya

(4) Mamwe masisitimu anoenderana nePA

SILIKE LYSI series silicone masterbatchinogona kugadziriswa nenzira imwecheteyo neresin carrier yayakavakirwa. Inogona kushandiswa mumaitiro ekusanganisa melt ekare akadai seSingle / Twin screw extruders, uye injection molding. Musanganiswa chaiwo ne virgin polymer pellets unokurudzirwa.

Huwandu hwakasiyana hwekuwedzera hune mhedzisiro dzakasiyana, kana uchida kuvandudza mashandiro ekugadzirisa uye mashandiro epamusoro pezvinhu zvekugadzira mapurasitiki, unogona kubata SILIKE, uye tinogona kukupa mhinduro dzinoshanda kuti zvigadzirwa zvako zvikwikwidzane.

Tel: +86-28-83625089/+ 86-15108280799 Email: amy.wang@silike.cn

Webhusaiti:www.siliketech.com

Nguva yekutumira: Kurume-07-2024