Nhanganyaya yePolyolefins neFirimu Extrusion

Mapolyolefin, rudzi rwezvinhu zvikuru zvakagadzirwa kubva kumaorefin monomers akadai se ethylene ne propylene, ndiwo mapurasitiki anonyanya kugadzirwa uye kushandiswa pasi rose. Kuwanda kwawo kunobva mukusanganiswa kwezvinhu zvakasiyana-siyana, kusanganisira mutengo wakaderera, kugona kugadzikiswa zvakanaka, kugadzikana kwemakemikari kwakanaka, uye hunhu hwemuviri hunoenderana. Pakati pemashandisirwo akasiyana-siyana emapolyolefin, zvigadzirwa zvemafirimu zvine chinzvimbo chikuru, zvichiita mabasa akakosha mukurongedza chikafu, kufukidza kwekurima, kurongedza kwemaindasitiri, zvigadzirwa zvekurapa nezvehutsanana, uye zvinhu zvemazuva ese zvinoshandiswa nevanhu. Ma polyolefin resins anonyanya kushandiswa pakugadzira mafirimu anosanganisira polyethylene (PE) - inosanganisira Linear Low-Density Polyethylene (LLDPE), Low-Density Polyethylene (LDPE), uye High-Density Polyethylene (HDPE) - uye polypropylene (PP).

Kugadzirwa kwemafirimu epolyolefin kunonyanya kushandiswa pakugadzira tekinoroji yekubvisa mafirita, neBlown Film Extrusion neCast Film Extrusion zviri izvo zvinhu zviviri zvakakosha.

1. Maitiro Ekuwedzera Mafirimu Akaputika

Kuburitsa firimu rinoputika ndeimwe yenzira dzakajairika dzekugadzira mafirimu epolyolefin. Nheyo huru inosanganisira kuburitsa polymer yakanyungudutswa yakatwasuka yakatwasuka ichikwira nepaseji yeannular, zvichigadzira parison ine madziro matete. Zvadaro, mhepo yakamanikidzwa inopinzwa mukati mepaseji iyi, zvichiita kuti iputike kuita bubble ine dhayamita yakakura kupfuura yedhayamita. Sezvo bubble richikwira, rinotonhodzwa zvine simba uye rinosimbiswa neringi yemhepo yekunze. Bhobho rinotonhodzwa rinozopunzirwa neseti yemaroller e nip (kazhinji kuburikidza nefuremu inodonha kana A-frame) uye rinozodhonzwa nemaroller e traction risati raputirwa paroli. Maitiro efirimu rinoputika anowanzo buritsa mafirimu ane biaxial orientation, zvichireva kuti anoratidza kuenzana kwakanaka kwehunhu hwemakanika mune zvese zviri zviviri nzira yemuchina (MD) uye nzira inochinjika (TD), senge simba rekudhonza, kuramba kubvaruka, uye simba rekukanganisa. Ukobvu hwefirimu uye hunhu hwemakanika zvinogona kudzorwa nekugadzirisa chiyero chekuputika (BUR - chiyero chedhayamita yebubble kune dhayamita yekufa) uye chiyero chekudhonza-kudzika (DDR - chiyero chekumhanya kwekutorwa kusvika kumhanya kwekubvisa).

2. Maitiro Ekuwedzera Mafirimu Akakandwa

Kuburitsa firimu reCast firimu ndeimwe nzira yakakosha yekugadzira mafirimu epolyolefin, inonyanya kukodzera kugadzira mafirimu anoda hunhu hwepamusoro hwe optical (semuenzaniso, kujeka kwakanyanya, kupenya kwakanyanya) uye kufanana kwakanaka kweukobvu. Mukuita uku, polymer yakanyungudutswa inoburitswa yakatwasuka kuburikidza ne flat, slot-type T-die, ichigadzira webhu yakanyungudutswa yakafanana. Webhu iyi inozobva yakweverwa nekukurumidza pamusoro peimwe kana kupfuura high-speed, inotonhorera mukati me cool rolls. Kunyunguduka kunokurumidza kuoma kana yabata pamusoro pe cold roll. Cast firimu inowanzova nehunhu hwakanaka hwe optical, kunzwa kwakapfava, uye kupisa kwakanaka. Kudzora kwakaringana pamusoro pe die lip gap, chill roll temperature, uye rotational speed zvinobvumira kudzora kwakarurama kweukobvu hwefirimu uye kunaka kwepamusoro.

Matambudziko matanhatu epamusoro ePolyolefin Film Extrusion

Pasinei nekukura kwetekinoroji yekubvisa mapurasitiki, vagadziri vanowanzosangana nematambudziko akawanda ekugadzirisa mapurasitiki mukugadzirwa kwemafirimu epolyolefin, kunyanya pavanenge vachiedza kuwana simba rakawanda, kushanda zvakanaka, magauge matete, uye pavanoshandisa maresini matsva anoshanda zvakanyanya. Matambudziko aya haangokanganisi kugadzikana kwekugadzirwa chete asiwo anokanganisa zvakananga kunaka kwechigadzirwa chekupedzisira uye mutengo. Matambudziko makuru anosanganisira:

1. Kupwanyika Kweganda (Sharkskin): Uku ndiko kumwe kwezvikanganiso zvakajairika mukubuda kwefirimu repolyolefin. Zvichienderana nehukuru hwema "macroscopic", zvinoonekwa se "periodic transverse ripples" kana "unstraight" pamusoro pefirimu, kana muzviitiko zvakakomba, "distortions" dzakanyanya kuoneka. Kupwanyika kwekunyunguduka kunonyanya kuitika kana "shear rate" yekunyunguduka kwepolymer kunobuda mu "die" ichidarika kukosha kwakakosha, zvichikonzera "stick-slip oscillations" pakati pe "die wall" ne "bulk melt", kana kuti "extensional stress" pakubuda kwe "die exit" ichidarika simba rekunyunguduka. Kukanganisa uku kunokanganisa zvakanyanya "optical properties" yefirimu (clearity, gloss), "smoothness" ye "surface", uye kunogonawo kuderedza "mechanical and barrier properties".

2. Die Drool / Die Build-up: Izvi zvinoreva kuunganidzwa zvishoma nezvishoma kwezvigadzirwa zvekuora kwepolymer, zvikamu zvishoma zvehuremu hwemamorekuru, zvinowedzera zvisina kupararira zvakanaka (semuenzaniso, pigments, antistatic agents, slip agents), kana magels kubva mu resin pamucheto we die lip kana mukati me die cavity. Madhipoziti aya anogona kubva panguva yekugadzira, zvichisvibisa pamusoro pefirimu uye zvichikonzera zvikanganiso zvakaita semagels, mitsetse, kana kukwenya, nokudaro zvichikanganisa chitarisiko chechigadzirwa uye mhando. Muzviitiko zvakakomba, die build-up inogona kuvhara nzira yekubuda nayo, zvichikonzera kusiyana kwemageji, kubvarura firimu, uye pakupedzisira kumanikidza kuvharwa kwemitsara yekugadzira yekuchenesa die, zvichikonzera kurasikirwa kukuru mukubudirira kwekugadzira uye kutambisa zvinhu zvisina kugadzirwa.

3. Kumanikidzwa Kwakanyanya uye Kuchinja-chinja Kwemhepo: Mune mamwe mamiriro ezvinhu, kunyanya pakugadzira maresini ane viscosity yakakura kana kushandisa ma die gaps madiki, kumanikidzwa kuri mukati me extrusion system (kunyanya pamusoro pe extruder ne die) kunogona kukwira zvakanyanya. Kumanikidzwa kwakanyanya hakungowedzeri kushandiswa kwesimba chete asiwo kunokonzera njodzi kuhupenyu hwemidziyo (semuenzaniso, sikuruu, barrel, die) uye kuchengetedzeka. Uyezve, kuchinja-chinja kwe extrusion pressure kunokonzera zvakananga kusiyana kwekunyunguduka kwemhepo, zvichikonzera ukobvu husina kufanana hwefirimu.

4. Kuburitswa Kwezvinhu Zvishoma: Kuti vadzivise kana kuderedza matambudziko akadai sekupwanyika kwemafuta uye kuungana kwemafuta, vagadziri vanowanzo manikidzwa kuderedza kumhanya kwescrew ye extruder, nokudaro vachideredza kubuda kwemutsetse wekugadzira. Izvi zvinokanganisa zvakananga kushanda zvakanaka kwekugadzira uye mutengo wekugadzira payuniti yega yega yechigadzirwa, zvichiita kuti zviome kusangana nezvinodiwa nemusika zvemafirimu makuru, asingadhuri.

5. Kuoma kweGauge Control: Kusagadzikana mukuyerera kwekunyunguduka, kupararira kwetembiricha isina kufanana padhiri, uye kuungana kwedhiri zvinogona kukonzera kusiyana kweukobvu hwefirimu, zvese zvakachinjika uye zvakareba. Izvi zvinokanganisa mashandiro efirimu anotevera uye hunhu hwekushandisa kwekupedzisira.

6. Kuchinja-chinja kweResin Kwakaoma: Pakuchinja pakati pemhando dzakasiyana kana magiredhi ema polyolefin resins, kana pakuchinja mavara emasterbatches, zvinhu zvakasara kubva pakumhanya kwekare zvinowanzova zvakaoma kubvisa zvachose kubva muextruder zvofa. Izvi zvinotungamira mukubatana kwezvinhu zvekare nezvitsva, kugadzira zvinhu zvinoshanduka, kuwedzera nguva yekuchinja, uye kuwedzera mwero wezvimedu.

Matambudziko aya akajairika ekugadzirisa anodzivisa kuedza kwevagadziri vemafirimu epolyolefin kusimudzira kunaka kwechigadzirwa uye kushanda zvakanaka kwekugadzira, uye zvakare zvinopa zvipingamupinyi pakushandiswa kwezvinhu zvitsva uye matekiniki epamusoro ekugadzirisa. Nokudaro, kutsvaga mhinduro dzinoshanda dzekukunda matambudziko aya kwakakosha pakukura kwakasimba uye kwakanaka kweindasitiri yese yepolyolefin extrusion.

Mhinduro dzePolyolefin Film Extrusion Process: Polymer Processing Aids (PPAs)

Polymer Processing Aids (PPAs) zvinhu zvinobatsira zvikuru zvine kukosha kukuru mukuvandudza maitiro e rheological e polymer melts panguva yekubuda uye kugadzirisa kushanda kwayo nenzvimbo dzemidziyo, nokudaro zvichikunda matambudziko akasiyana-siyana ekugadzirisa uye kuwedzera kushanda zvakanaka kwekugadzira uye kunaka kwechigadzirwa.

1. MaPPA akavakirwa paFluoropolymer

Maumbirwo eMakemikoro uye Hunhu: Aya ndiwo maPPA anonyanya kushandiswa zvakanyanya, akakura muhunyanzvi, uye anoshanda zvakanyanya. Anowanzova mahomopolymer kana macopolymer akavakirwa pamamonomer efluoroolefin akadai sevinylidene fluoride (VDF), hexafluoropropylene (HFP), uye tetrafluoroethylene (TFE), uye mafluoroelastomers ndiwo anonyanya kumiririrwa. Maketani emamorekuru emaPPA aya akapfuma muzvisungo zveCF zvine simba guru, low-polarity, izvo zvinopa hunhu hwakasiyana hwefizikisi: simba rakaderera repamusoro (rakafanana nepolytetrafluoroethylene/Teflon®), kugadzikana kwakanaka kwekupisa, uye kusagadzikana kwemakemikari. Zvakakosha kuti maPPA efluoropolymer anowanzo ratidza kusawirirana kwakanaka nema polyolefin matrices asiri epolar (senge PE, PP). Kusawirirana uku ndicho chinhu chakakosha kuti afambe zvakanaka achienda kunzvimbo dzesimbi dzedi, kwaanoumba dynamic lubricating coating.

Zvigadzirwa Zvinomiririra: Makambani anotungamira mumusika wepasi rose we fluoropolymer PPAs anosanganisira Chemours' Viton™ FreeFlow™ series uye 3M's Dynamar™ series, ayo ane mugove wakakura wemusika. Pamusoro pezvo, mamwe ma fluoropolymer grades kubva kuArkema (Kynar® series) naSolvay (Tecnoflon®) anoshandiswawo se, kana kuti zvimwe zvikamu zvakakosha mu, PPA formulations.

2. Zvishandiso Zvekugadzirisa Zvakavakirwa paSilicone (PPAs)

Maumbirwo eMakemikoro uye Hunhu: Zvinhu zvikuru zvinoshanda mukirasi iyi yePPAs ipolysiloxanes, inowanzonzi silicones. Musana wepolysiloxane une maatomu esilicon neeoxygen anochinjana (-Si-O-), ane mapoka eorganic (kazhinji methyl) akabatana nemaatomu esilicon. Maumbirwo aya akasiyana emolekyulu anopa zvinhu zvesilicone simba shoma repamusoro, kugadzikana kwakanaka kwekupisa, kuchinjika kwakanaka, uye hunhu husina kunamira kune zvinhu zvakawanda. Kufanana ne fluoropolymer PPAs, silicone-based PPAs inoshanda nekufamba ichienda kunzvimbo dzesimbi dzemichina yekugadzirisa kuti igadzire layer yekuzora.

Mashandisirwo Azvo: Kunyangwe maPPA efluoropolymer achitonga chikamu che polyolefin film extrusion, maPPA akavakirwa pa silicone anogona kuratidza mabhenefiti akasiyana kana kugadzira mhedzisiro yekubatana kana akashandiswa mune mamwe mamiriro ekushandisa kana pamwe chete nemasisitimu e resin akasiyana. Semuenzaniso, anogona kutariswa kune mashandisirwo anoda ma coefficients akaderera zvakanyanya ekukweshana kana apo hunhu hwepamusoro hunodiwa kune chigadzirwa chekupedzisira.

Kutarisana Nekurambidzwa kweFluoropolymer kana Matambudziko Ekupa PTFE?

Gadzirisa Matambudziko ePolyolefin Film Extrusion nePFAS-Free PPA Solutions-Zvimwe zvinhu zveSILIKE's Fluorine Polymer

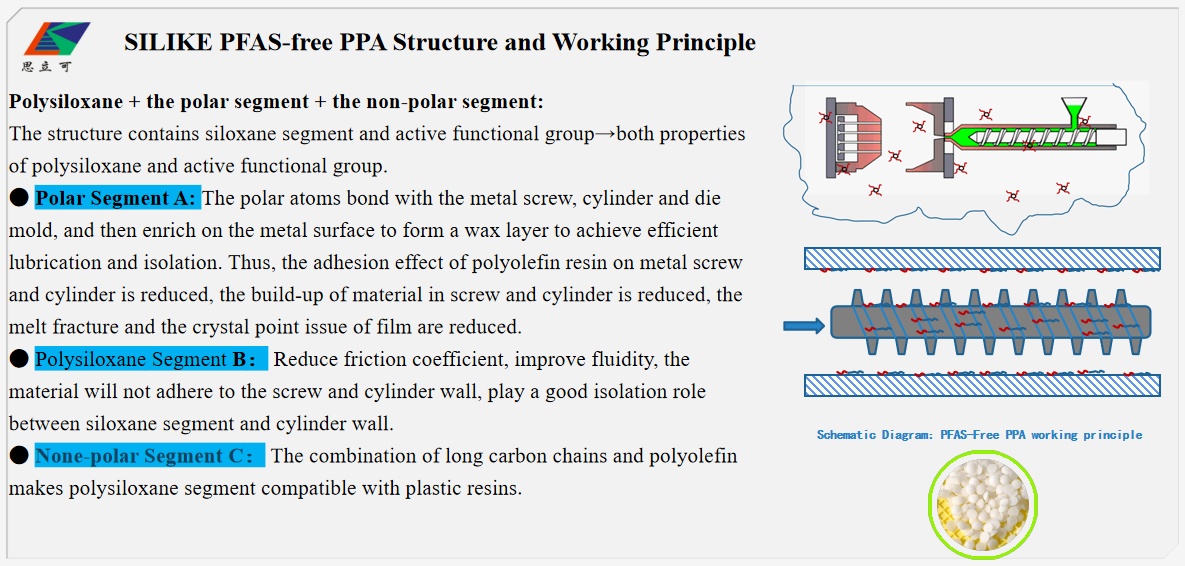

SILIKE inoshandisa nzira yekukurumidza kugadzira zvigadzirwa zvayo zveSILIMER, ichipa zvinhu zvitsvaZvishandiso zvekugadzirisa polymer zvisina PFAS (PPAS)). Mutsetse uyu wezvigadzirwa wakazara une maPPA asina PFAS 100%,PPA isina fluorine Polymer zvinowedzerauyeMabatch ePPA asina PFAS uye asina fluorine.Nakubvisa kudiwa kwe fluorine additives, izvi zvinobatsira zvikuru mukuvandudza maitiro ekugadzira eLLDPE, LDPE, HDPE, mLLDPE, PP, uye maitiro akasiyana-siyana epolyolefin film extrusion. Zvinoenderana nemitemo yemazuva ano yezvakatipoteredza ukuwo zvichiwedzera kushanda zvakanaka kwekugadzira, kuderedza nguva yekushanda, uye kuvandudza mhando yezvigadzirwa. MaPPA asina PFAS eSILIKE anounza mabhenefiti kuzvigadzirwa zvekupedzisira, kusanganisira kubvisa kupwanyika kweganda rakanyunguduka (sharkskin), kutsvedzerera kwakawedzerwa, uye kunaka kwepamusoro.

Kana uri kunetseka nekukanganiswa kwekurambidzwa kwefluoropolymer kana kushomeka kwePTFE mumaitiro ako ekubvisa polymer, SILIKE inopadzimwe nzira dzinoshandiswa panzvimbo pe fluoropolymer PPAs/PTFE, Zvimwe zvisina PFAS zvekugadzira mafirimuzvakagadzirirwa kuzadzisa zvaunoda, pasina shanduko dzemaitiro dzinodiwa.

Nguva yekutumira: Chivabvu-15-2025