Nzira yekupenda mapurasitiki nemavara ndiyo inonyanya kushandiswa muindasitiri yekugadzira mapurasitiki. Chimwe chezvinhu zvinonyanya kukosha zvinoratidza mashandiro e masterbatch kupararira kwayo. Kupararira kunoreva kupararira kwakafanana kwemavara mukati mepurasitiki. Ingave mukugadzira majekiseni, kuburitsa mapurasitiki, kana kugadzira mabhuroko, kupararira kusina kunaka kunogona kutungamira mukupararira kwemavara kusina kuenzana, mitsetse isina kuenzana, kana madonhwe muchigadzirwa chekupedzisira. Nyaya iyi inyaya huru kune vagadziri, uye kunzwisisa zvikonzero nemhinduro kwakakosha pakuchengetedza mhando yechigadzirwa.

Zvinokonzera Kupararira Kusina Kunaka muColor Masterbatch

Kuungana kwePigments

Masterbatch musanganiswa wepigment wakanyanya kuwanda, uye mapoka makuru epigment idzi anogona kukanganisa zvakanyanya kupararira. Pigments dzakawanda, dzakadai setitanium dioxide necarbon black, dzinowanzobatana. Kusarudza mhando chaiyo uye saizi yepigment zvichienderana nekugadzirwa kwekupedzisira uye nzira yekugadzirisa kwakakosha kuti uwane kupararira kwakanaka.

Mhedzisiro yeElectrostatic

Mazhinji mamasterbatches haana antistatic agents. Kana masterbatch ikasanganiswa nezvinhu zvisina kugadzirwa, magetsi asingachinji anogona kugadzirwa, zvichikonzera kusanganiswa kusina kuenzana uye kupararira kwemavara asingachinji muchigadzirwa chekupedzisira.

Nhamba Yekunyunguduka Isina Kufanira

Vatengesi vanowanzo sarudza maresini ane indekisi yekunyunguduka yakawanda semutakuri wemasterbatch. Zvisinei, indekisi yekunyunguduka yakakwirira haisi nguva dzose iri nani. Indekisi yekunyunguduka inofanira kusarudzwa nokungwarira kuti ienderane nehunhu hwemuviri uye zvinodiwa pamusoro pechigadzirwa chekupedzisira, pamwe nehunhu hwekugadzirisa kwemasterbatch. Indekisi yekunyunguduka yakaderera zvakanyanya inogona kukonzera kusapararira zvakanaka.

Chiyero Chekuwedzera Chakaderera

Vamwe vatengesi vanogadzira masterbatch ine chiyero chidiki chekuwedzera kuti vaderedze mitengo, izvo zvinogona kukonzera kusapararira kwakakwana mukati mechigadzirwa.

Sisitimu Yekupararira Isina Kukwana

Zvinodiridza zvinowedzerwa panguva yekugadzira masterbatch kuti zvibatsire kuputsa mapoinzi epigment. Kana zvikashandiswa zvisirizvo, zvinogona kukonzera kusapararira zvakanaka kwemafuta.

Kusawirirana kwehuwandu hwevanhu

MaMasterbatches anowanzova ne pigments dzine density yakakura, dzakadai setitanium dioxide, ine density inosvika 4.0g/cm³. Izvi zvakakwirira zvakanyanya kupfuura density yemaresins akawanda, zvichikonzera sedimentation yemasterbatch panguva yekusanganisa, zvichikonzera kupararira kwemavara kusina kuenzana.

Kusarudzwa Kwemutakuri Asina Kufanira

Kusarudzwa kweresin inotakura zvinhu, iyo inobata pigments nezvimwe zvinowedzerwa, kwakakosha. Zvinhu zvakaita serudzi, huwandu, giredhi, uye kunyunguduka kwemuchina, pamwe nekuti uri muchimiro cheupfu here kana kuti chepellet, zvese zvinogona kukanganisa kunaka kwekupararira kwekupedzisira.

Mamiriro Ekugadzirisa

Mamiriro ekugadzirisa masterbatch, kusanganisira rudzi rwemichina, maitiro ekusanganisa, uye matekiniki ekuisa pelletizing, ane basa guru mukupararira kwayo. Sarudzo dzakadai sekugadzira michina yekusanganisa, magadzirirwo emasikuruu, uye maitiro ekutonhodza zvese zvinokanganisa mashandiro ekupedzisira emasterbatch.

Mhedzisiro yeMaitiro Ekuumba

Maitiro chaiwo ekuumba, akadai sekuumba nejekiseni, anogona kukanganisa kupararira. Zvinhu zvakaita sekupisa, kumanikidzwa, uye nguva yekubata zvinogona kukanganisa kufanana kwekupararira kwemavara.

Kupfeka Zvishandiso

Midziyo inoshandiswa mukugadzira mapurasitiki, senge screws dzakasakara, inogona kuderedza simba rekuchekerera, zvichiita kuti masterbatch isapararire zvakanyanya.

Dhizaini yeFomu

Pakuumbwa kwejekiseni, nzvimbo yegedhi nezvimwe zvinhu zvekugadzira mold zvinogona kukanganisa kugadzirwa kwechigadzirwa nekupararira kwacho. Pakubuda kwechinhu, zvinhu zvakaita sekugadzirwa kwedivha uye tembiricha zvinogonawo kukanganisa kunaka kwekupararira kwacho.

Mhinduro dzekuvandudza kupararira kwemavara eMasterbatch, zvinosanganisa ruvara uye makemikari

Kana paine kusapararira kwakanaka, zvakakosha kugadzirisa dambudziko nenzira yakarongeka:

Batirana Pamwe Chete muDzidziso: Kazhinji, nyaya dzekupararira kwemabasa hadzingokonzerwa nezvinhu kana maitiro chete. Kushanda pamwe chete pakati pemapato ese akakosha, kusanganisira vatengesi vezvinhu, mainjiniya emabasa, nevagadziri vemidziyo, ndiko kwakakosha pakuziva nekugadzirisa zvikonzero zvikuru.

Gadzirisa Sarudzo yePigment:Sarudza pigments dzine saizi yakakodzera yezvidimbu uye mhando yakakodzera yekushandisa.

Kudzora Magetsi Asingachinji:Isa mishonga inorwisa static kana zvichidikanwa kudzivirira kusawirirana kusina kuenzana.

Gadzirisa Nhamba Yekunyunguduka:Sarudza vatakuri vane indekisi yekunyunguduka inoenderana nemamiriro ekugadzirisa uye zvinodiwa zvechigadzirwa.

Ongororo yeZviyero zvekuwedzera: Iva nechokwadi chekuti masterbatch yawedzerwa muhuwandu hwakakwana kuti iparadzirwe.

Gadzirisa Sisitimu Yokupararira:Shandisa zvinhu zvinoparadzira uye mafuta akakodzera kuti uwedzere kuputsika kwemavara epigment.

Kuwanda kwehuwandu:Funga nezvekuwanda kwepigment nema carrier resins kudzivirira kudonha kwevhu panguva yekugadzirisa.

Magadzirirwo Ekugadzirisa Zvakanaka:Gadzirisa marongero emidziyo, akadai setembiricha uye marongero emasikuruu, kuti uwedzere kupararira kwayo.

Unyanzvi hutsvaMhinduro dzekuvandudza kupararira kwemavara eMasterbatch

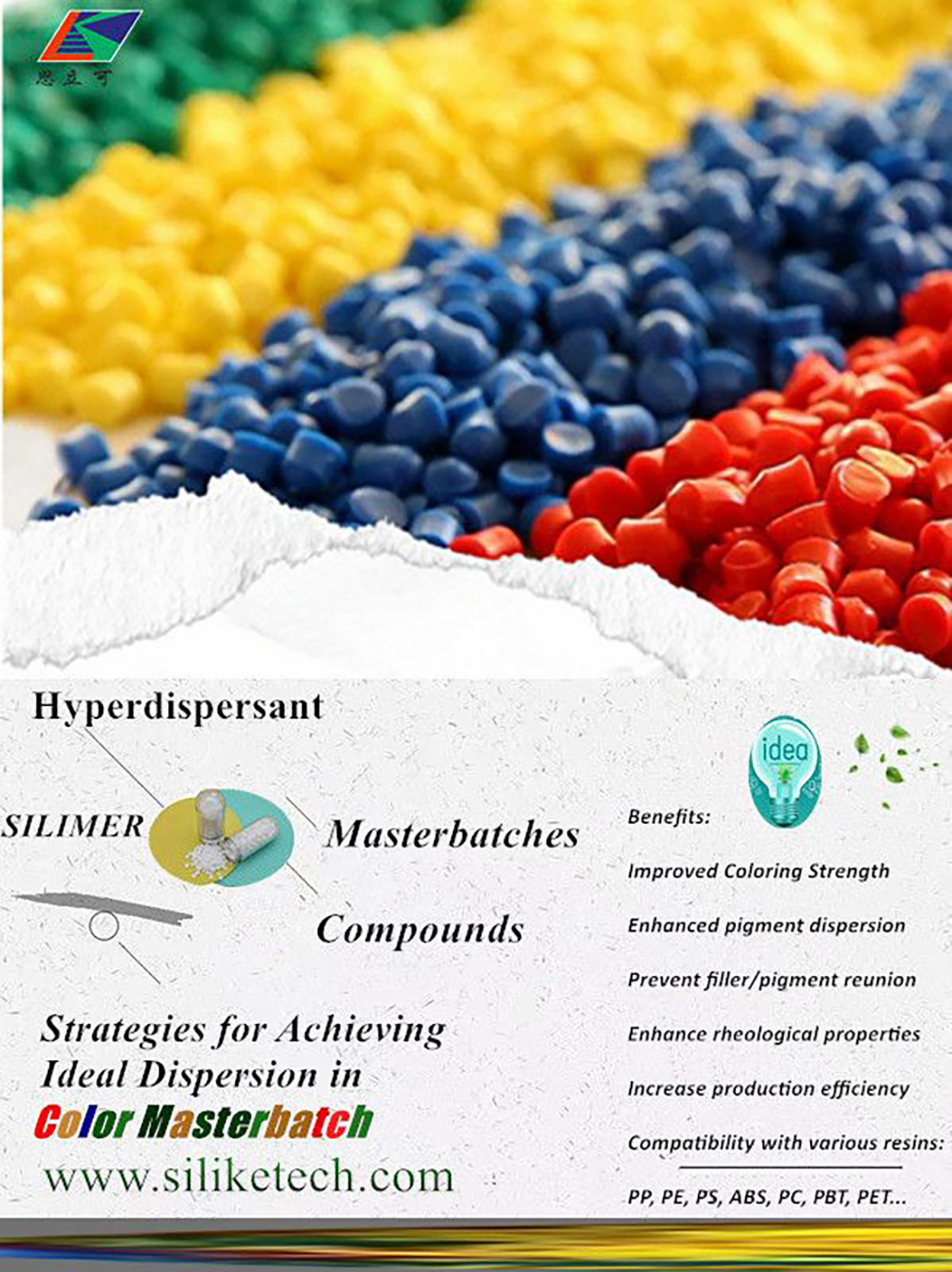

Novel Silicone hyperdispersant, nzira inoshanda yekugadzirisa Uneven Dispersion muColor Masterbatches neSILIKE SILIMER 6150.

SILIMER 6150iwakisi yesilicone yakagadziriswa inoshanda se hyperdispersant inoshanda, yakagadzirirwa kusimudzira mhando yemavara akaomeswa, ma masterbatches, uye macompounds. Ingave iri single pigment dispersion kana kuti mavara akagadzirwa nenzira yakasarudzika, SILIMER 6150 inobudirira mukusangana nezvinodiwa zvakanyanya zvekupararira.

Azvakanakira zve SILIMER 6150mhinduro dze color masterbatch:

Kupararira Kwemavara Akawedzerwa: SILIMER 6150inoita kuti pigments dzipararire zvakaenzana mukati mepurasitiki, ichibvisa mitsetse yemavara kana madonhwe uye ichivimbisa kuti mavara acho akaenzana.

Simba Rakavandudzwa reKupenda:Nekugadzirisa kupararira kwepigment,SILIMER 6150inowedzera simba rekupenda, zvichibvumira vagadziri kuwana simba reruvara rwavanoda neruvara rushoma, zvichikonzera kugadzirwa kwacho kunoshanda uye kusingadhuri.

Kudzivirira Kusanganazve kweFiller nePigment: SILIMER 6150zvinobudirira zvinodzivirira pigments nemafillers kuti asaungane pamwe chete, zvichiita kuti zvive zvakagadzikana uye zvinopararira panguva yese yekugadzirisa.

Hunhu Huri Nani hweRheological: SILIMER 6150Hazvingobatsiri chete kupararira kwepurasitiki asiwo zvinowedzera hunhu hwe rheological hwe polymer melt. Izvi zvinoita kuti kugadzirwa kwayo kuve kwakapfava, kuderera kwekusimba kwesimbi, uye kuvandudzwa kwehunhu hwekuyerera kwemvura, izvo zvakakosha pakugadzirwa kwepurasitiki yemhando yepamusoro.

IKubudirira Kwekugadzira uye Kuderedza Mari Yacho: Nekupararira kwakawedzerwa uye hunhu huri nani hwe rheological,SILIMER 6150inowedzera kushanda zvakanaka kwekugadzira, zvichibvumira nguva dzekugadzirisa nekukurumidza uye kuderedza marara ezvinhu, zvichideredza mari yekugadzira.

Kuenderana Kwakakura: SILIMER 6150Inoenderana nemhando dzakasiyana dzemaresini, anosanganisira PP, PE, PS, ABS, PC, PET, uye PBT, zvichiita kuti ive sarudzo yakakodzera kushandiswa kwakasiyana-siyana muindasitiri ye masterbatch uye compounds plastics.

Wedzera kugadzirwa kwemavara ako emasterbatch uchishandisaSILIMER 6150kuti pave nekupararira kwepigment kwakanaka uye kuti chigadzirwa chishande zvakanaka. Bvisa mitsetse yemavara uye wedzera kushanda zvakanaka. Usapotsa—vandudza kupararira, deredza mitengo, uye wedzera kunaka kwemasterbatch yako.Bata Silike nhasi!Nhare: +86-28-83625089, Email:amy.wang@silike.cn,Shanyirawww.siliketech.comkuti uwane rumwe ruzivo.

Nguva yekutumira: Nyamavhuvhu-15-2024