Slip Silicone Masterbatch SF110 Yemafirimu Akapfurwa eBOPP/CPP

Tsananguro

SF110 imhando itsva ye smooth masterbatch yakagadzirwa uye yakagadzirwa neBOPP/CPP film products. Ne poly dimethyl siloxane yakagadziriswa semushonga unoshanda, chigadzirwa ichi chinokunda zvikanganiso zvikuru zve general slip additives, kusanganisira slip agent inonaya nguva dzose kubva pamusoro pefirimu, kushanda kwayo kunoderera nekufamba kwenguva uye tembiricha ichiwedzera, hwema, nezvimwewo.

SF110 slip masterbatch yakakodzera BOPP/CPP film blowing molding, casting molding, processing performance yakafanana ne base material, hapana chikonzero chekuchinja.

Mamiriro ekugadzirisa: anoshandiswa zvakanyanya mukugadzira firimu reBOPP/CPP rinoputika, firimu rekukanda uye kuputira kwekunze nezvimwewo.

Zvimiro zveChigadzirwa

| Giredhi | SF110 |

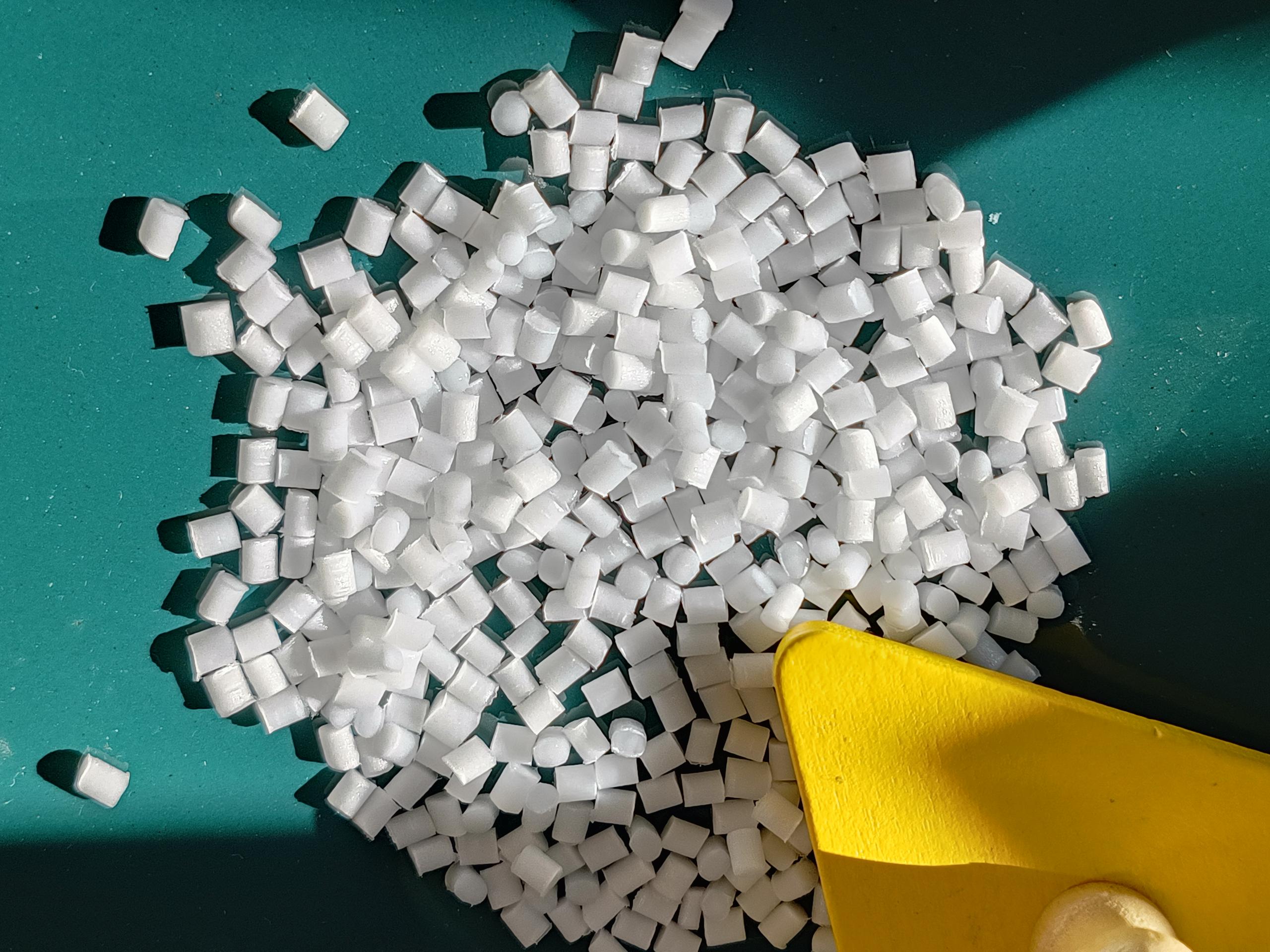

| Chitarisiko | pepa jena |

| MI(230℃,2.16kg)(g/10min) | 10~20 |

| Kuwanda kwepamusoro()kg/cm3) | 500~600 |

| Carrier | PP |

| Vzviri mukati zvinopera()%) | ≤0.2 |

Mabhenefiti

1. Kana firimu reSF110 rawedzerwa, chiyero chekukweshana hachina simba guru pakupisa.

2. Mukushanda kwekugadzirisa, hazvizoiti kuti midziyo ibude, hazvizobudisi kirimu chena, uye zvichawedzera nguva yekuchenesa michina.

3. SF110 inogona kupa friction coefficient yakaderera uye haina simba guru pakujeka kwefirimu.

4. Huwandu hwakanyanya hweSF110 mufirimu i10% (kazhinji 5~10%).

5. Inifinoda kushanda zvakanaka, inogona kuwedzera masterbatch isingachinji.

Zvakanakira zvekushandisa

Kushanda kwepamusoro: hapana mvura inonaya, kuderedza kukwirirana kweganda pamusoro pefirimu, kunatsiridza kutsetseka kweganda;

Kushanda zvakanaka kwekugadzirisa: kunyorova kwekugadzirisa, kuvandudza kushanda zvakanaka kwekugadzirisa.

Kushandiswa kwakajairika

Kutsvedza uye kudzivirira kuvharika kwefirimu rePP kwakapfava, kunoderedza kukweshana kwepamusoro, hakupindi mvura, uye kune kuvandudzwa kwakanaka pahunhu hwekugadzirisa.

Mashandisirwo

· SF110 slip masterbatch inoshandiswa paBOPP/CPP film blowing molding uye casting molding uye mashandiro ekugadzirisa akafanana nebase material, hapana chikonzero chekuchinja.

· Chiyero chinowanzova 2 ~ 10%, uye chinogona kugadzirisa zvinhu zvichienderana nehunhu hwechigadzirwa chezvinhu zvakagadziriswa uye ukobvu hwemafirimu ekugadzira.

· Munguva yekugadzira, wedzera SF110 slip masterbatch zvakananga kune zvinhu zve substrate, wozosanganisa zvakaenzana wozoisa mu extruder.

Pasuru

25Kg / bhegi, bhegi repepa rehunyanzvi

Kuchengetera

Tungamirwa semakemikari asina njodzi. Chengeta munzvimbo inotonhorera, ine mhepo yakanaka.

Nguva yesherufu

Hunhu hwepakutanga hunoramba hwakafanana kwemwedzi makumi maviri nemana kubva pazuva rekugadzirwa, kana hukachengetwa munzvimbo inorayirwa.

ZVIMWE ZVESILICONE ZVEMAHARA UYE MIFANANIDZO YESI-TPV ZVINOPFUURA MAGREYI 100

Rudzi rwemuenzaniso

$0

- 50+

mamakisi Silicone Masterbatch

- 10+

mamakisi eSilicone Powder

- 10+

mamakisi Anti-kukwenya Masterbatch

- 10+

mamakisi Anti-abrasion Masterbatch

- 10+

mamakisi Si-TPV

- 8+

mamakisi eSilicone Wakisi

-

Runhare

-

E-mail

-

WhatsApp

WhatsApp

-

Pamusoro

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur